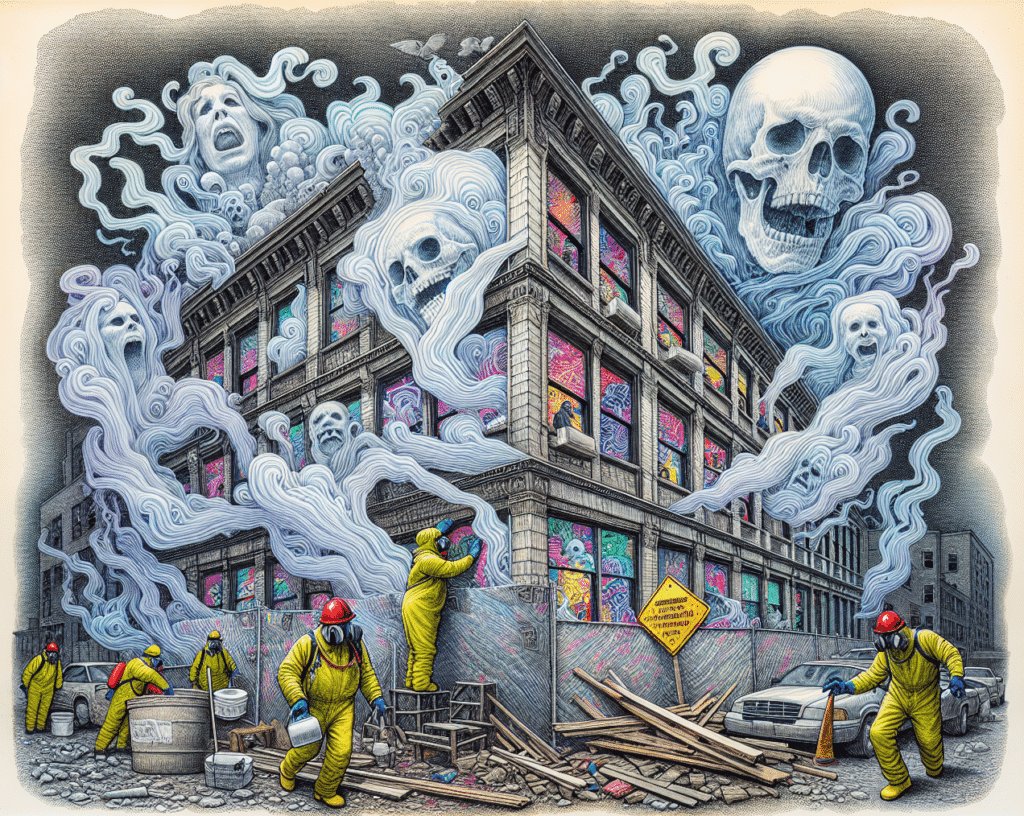

When dealing with hazardous materials found on construction sites, knowing what they are, the risks involved, and how to manage them safely is crucial. This guide provides an essential overview of common hazards like lead, asbestos, and silica dust, and outlines effective strategies for safe handling, compliance with regulations, and protective measures for workers on-site.

Key Takeaways

- Identifying hazardous materials such as lead, asbestos, mercury, and silica dust is critical for occupational safety on construction sites.

- Effective safety measures include the use of personal protective equipment (PPE), implementing ventilation systems, and regular health monitoring for workers.

- Compliance with OSHA guidelines and state regulations is essential to ensure safe management of hazardous materials and prevent environmental contamination.

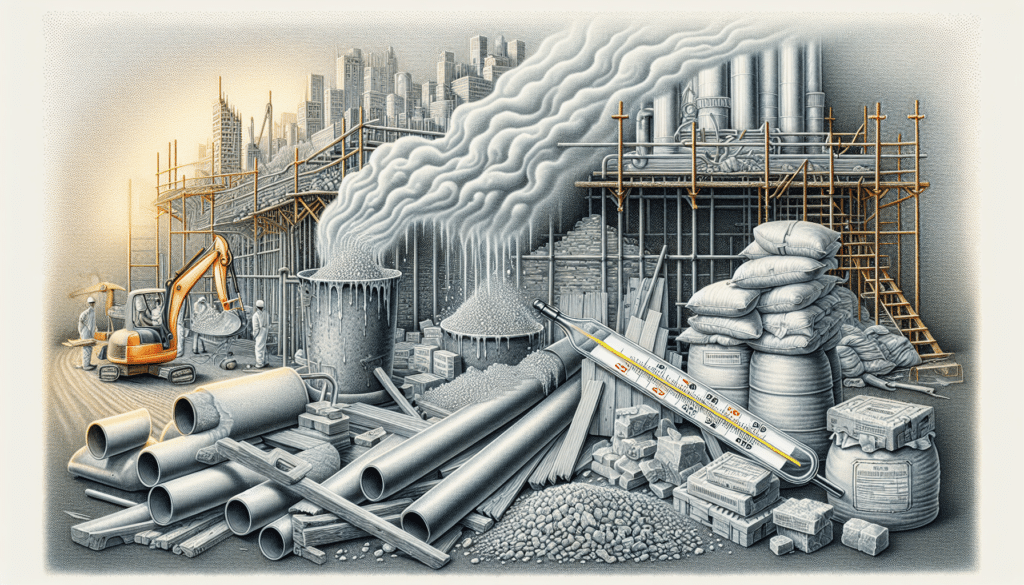

Understanding the Risks: Identifying Hazardous Materials on Construction Sites

Construction sites are filled with a myriad of materials, each with their own hidden narratives of risk. Hazardous materials such as lead, asbestos, mercury, mold, and silica dust can pose a spectrum of health risks. Recognizing these threats is the first step in fortifying occupational safety.

Lead-Based Paint and Coatings

Among the most common hazardous materials is lead paint. It is often found in various construction materials like paint and other outer coatings. While necessary for building preservation, lead materials, if inhaled or ingested, can cause severe and long lasting health issues.

Asbestos: The Hidden Hazard

Asbestos is located in materials like tiles and insulation. Its fibers, once disturbed, become airborne threats that can lead to severe health issues, necessitating stringent removal protocols to protect those who build and inhabit these spaces.

Silica Dust: A Tiny Menace

Silica dust materializes from construction materials such as sand, stone, and concrete. When they’re cut, drilled, or blasted, they release a dust that can scar lungs, making it a formidable hazard on any job site.

Protective Measures: Equipping Workers for Safety

After the hazards have been properly identified, it is important to understand the proper equipment designed to defend workers from these substances.

The Role of PPE in Construction Safety

The role of personal protective equipment (PPE) in construction safety cannot be overstated. Helmets to shield from falling debris, goggles to guard against piercing dust, gloves to ward off chemical burns – these are the tools that, when used properly, help protect workers from potential hazards.

Implementing Effective Ventilation Systems

Beyond PPE, effective ventilation systems can help filter any maladies that may taint the atmosphere and ensure that workers can take a deep breath without fear of what they’re inhaling. Proper use of cleaning fluids can also contribute to maintaining a safe environment on site.

Regular Health Monitoring for On-site Workers

Regular health monitoring and health administration is encouraged to help detect any harm that may have slipped through, despite the safety precautions.

Safe Disposal and Environmental Considerations

Hazardous materials often found on construction sites must be handled with care. Safe waste disposal and environmental considerations are the principles construction workers uphold to avoid any potential contamination.

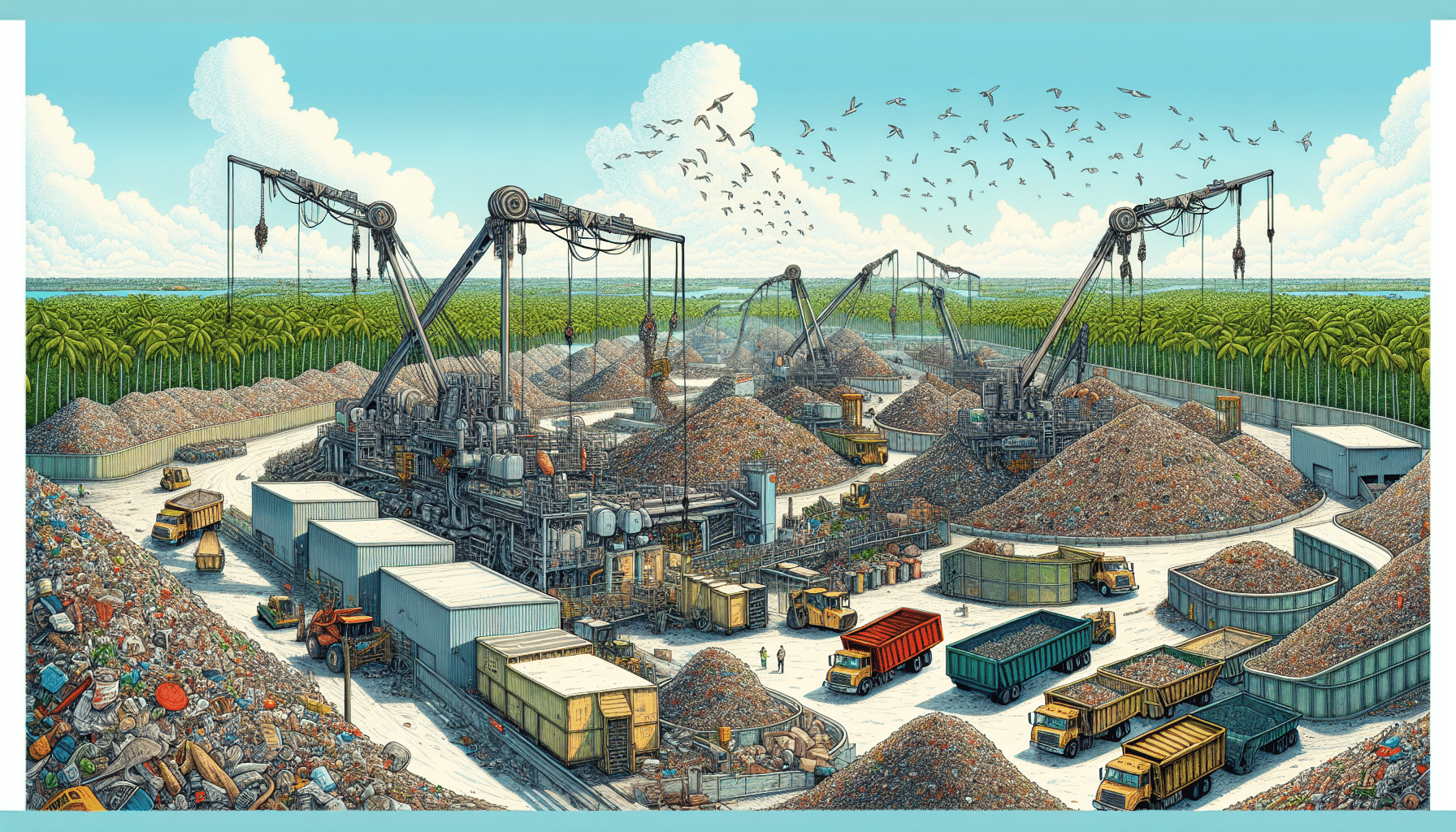

Handling and Disposing of Hazardous Building Debris

The disposal of hazardous building debris, including demolition debris, is a meticulous process that is governed by federal and state regulations. These regulations ensure the classification, containment, and conscientious disposal that keeps our environment, and worker health, in balance.

Mercury and Universal Waste Management

Mercury is a dangerous substance and should be handled with care. The proper management of mercury-containing devices and universal waste is necessary for minimizing exposure risks and safeguarding the well-being of construction workers.

Preventing Moisture and Mold Growth

Moisture and mold growth, if left unchecked, can become harmful. Preventing the site from mold and moisture buildup requires vigilance, proper ventilation, and a proactive approach to moisture control, all essential for maintaining a healthy construction environment.

Legal Compliance: Navigating Federal and State Regulations

Navigating the complex web of federal and state regulations is important to understand responsible construction practices. Understanding these regulations ensures that the structures we build are safe for both those who build them and those who will inhabit them.

Understanding OSHA Guidelines for Hazardous Substances

Understanding OSHA guidelines for hazardous substances can help construction workers navigate any potential hazards they might face on the job.

State-Specific Regulations on Hazardous Material Management

While federal regulations provide a baseline, state-specific regulations on hazardous material management often add layers of protection tailored to local nuances. These additional requirements help mitigate risks that might slip through broader regulations, reinforcing construction site safety.

Advanced Hazards: Polychlorinated Biphenyls (PCBs) and Other Chemicals

In the shadow of common construction materials lie common hazardous substances like polychlorinated biphenyls (PCBs) and other chemicals. These substances, often remnants of a past construction, linger with potential risks that demand advanced knowledge and handling to ensure they don’t cause potential harm.

The Threat of PCBs in Older Construction

PCBs in older construction necessitate awareness and precaution to prevent their harmful effects from affecting current and future generations. t Vigilance is important to avoid the harmful effects caused by these substances often found in older construction sites.

Tackling Rare and Complex Hazardous Materials

Rare and complex hazardous materials require specialized protection and procedures for construction safety. Encounters with hazardous materials demand a higher level of response to ensure that safety is not compromised.

Preventive Strategies: Avoiding Exposure to Hazards

Preventative strategies are the best defense we have in the ongoing battle against exposure to hazards. They are the practices that, when implemented, can prevent potential emergencies, focusing on avoidance as the key to safety.

Education and Training for Contractor Employees

The cornerstone of prevention lies in education and training for contractor employees. The ability to recognize hazards, the power to respond appropriately, and the forethought to protect oneself and others from the risks that permeate construction sites are of utmost importance for construction safety.

Safe Work Practices and Engineering Controls

Safe work practices and engineering controls are the tools and tactics that, when used effectively, can significantly reduce the likelihood of hazardous exposure. Safe work practices include meticulous planning, careful execution, and ongoing adaptation that keep safety at the forefront of every construction activity.

Emergency Response: What to Do When Exposed

Despite all precautions, emergencies can happen. When they do occur, a swift and effective emergency response is crucial. Knowing what to do when exposed to hazardous materials can be the difference between a minor incident and a major health crisis.

First Aid and Medical Attention for Acute Exposure

Time is of the essence when it comes to first aid and medical attention for acute exposure to hazardous substances. Quick, decisive action is necessary to mitigate the effects of exposure and ensure the best possible outcome for those affected.

Reporting Procedures and Remediation Plans

In the wake of an exposure event, the following steps are critical for recovery:

- Document every detail of the event.

- Understand the implications of the exposure.

- Develop a remediation plan to address the issues.

- Implement the plan to return to a state of safety.

These procedures and plans serve as the blueprint for recovery after an exposure event.

Summary

The management of hazardous materials is a critical element that safeguards the health of workers and the integrity of our built environment. It is important to understand the risks involved in construction and how to implement protective measures in case of an emergency. From legal compliance to emergency response, the layers of safety we weave into our practices are as vital as the structures we construct. Let this guide serve as the foundation upon which you build a safer, healthier world of construction.

Frequently Asked Questions

What are hazardous substances in construction?

Hazardous substances in construction include asbestos, lead, mercury, polychlorinated biphenyls (PCB), chlorofluorocarbons, and radioactive sources, and can be found in buildings of any age or condition.

What is HazMat in construction?

HazMat in construction refers to hazardous materials like asbestos, lead, PCBs, CFCs, heavy metals, and radioactivity, which can pose health and environmental risks.

How can workers protect themselves from exposure to hazardous materials?

To protect themselves from exposure to hazardous materials, workers should use personal protective equipment (PPE) and follow safe work practices and engineering controls. This includes wearing hard hats, safety glasses, gloves, and respirators.

What should be done if a worker is exposed to hazardous materials?

If a worker is exposed to hazardous materials, they should seek immediate medical attention, remove contaminated clothing, and follow emergency response procedures, including reporting the incident. Always prioritize safety in such situations.

Why is regular health monitoring important for construction workers?

Regular health monitoring is important for construction workers to detect health issues early, verify the effectiveness of health risk management systems, and ensure their overall well-being and safety.